Musical ideas have been recycled for hundreds of years, so why not the guitar strings that help make that music?

String manufacturer D’Addario estimates about 1.5 million pounds of strings end up in US landfill sites every year. However, old strings aren’t the only issue – making them can cause more environmental damage than musicians assume.

A D’Addario patent application in 2006, which outlined a new process to coat strings, described the environmental impact of its EXP brand of tarnish-resistant coated strings.

“This process is not environmentally friendly,” it wrote in the patent application. “The process generates offensive odors and requires careful environmental protection measures.”

Recycling old strings sounds like a simple solution but the reality is more challenging. Strings aren’t accepted by most local recycling programs because – unlike other recyclables – they’re made of complex metals and alloys, which differ by string. Recycling can potentially create more environmental issues than it solves as transporting and melting down small amounts of metals raises carbon emissions.

Nonetheless, D’Addario teamed up with global recycling organization TerraCycle back in 2016 to launch string recycling program Playback.

“To date, the D’Addario String Recycling Program has collected nearly 7 million instrument strings for recycling,” a TerraCycle spokesperson told Insideguitar.com in May 2021.

Consumers bring their used strings to hundreds of music stores in the US and place them in specially marked bins, which are then sent TerraCycle. They separate the metal and nylon strings, before melting down the metal, which is smelted into new metal alloys. The nylon is recycled into industrial plastic applications.

Playback accepts strings from any instrument or manufacturer and Martin officially joined the program in 2019. However, the program remains limited to the United States.

More marketing than environmental impact?

Not everyone is convinced that recycling strings is the best way to preserve the environment. Mimmo Peruffo, founder of string company Aquila Corde Armoniche, says the initiative only recovers a few grams of material every few weeks.

“Our company sees these initiatives of Martin and D’Addario as a marketing campaign and not as something that really helps the environment,” he told Inside-guitar.com.

“Instead of adhering to this recycling initiative, which in our opinion is purely symbolic and for advertising purposes, we think that other companies should do as we already do: introduce bio-based plastics, reduce the use of PVDF [a string polymer which contains fluorine] and really reduce the environmental impact of their packaging by eliminating all the superfluous content inside, as we have already been doing from some years.”

Aquila, which runs five extruder plants to manufacture its own strings, has discovered three bioplastics that can be used to make instrument strings. Its Zaffiro and Sugar trebles are made from 100% plant derivatives, which cuts carbon dioxide emissions in half during production. Its Bionylon strings, which are made from 63% plant derivatives, reduce carbon dioxide emissions by more than 30%.

Aquila says the material in Zaffiro makes these strings bright, similar to fluorocarbon strings, while Sugar (derived from sugar cane) produces more power and sustain than fluorocarbon without the harshness.

Reducing string set packaging

Most major string manufacturers are also trying to minimize their environmental impact by focusing on reduced packaging.

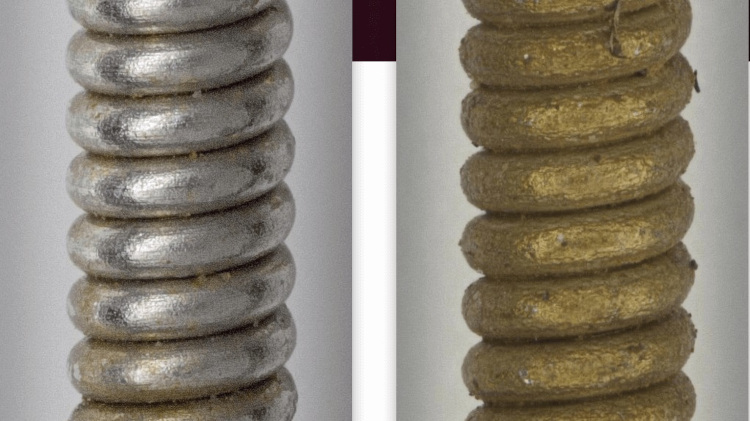

Peruffo says its not enough to just use recycled paper, manufacturers need to minimize use of metallic plastic bags, labels, and multiple bags for each string (silver-plated copper strings are still separately packaged otherwise they tend to become black).

“The paper in our bag is of course recycled and certified and we have made a big hole in the envelope whose purpose is not only to show the strings inside, but also to reduce the envelope weight/quantity to a minimum because you have to remember that the weight of the packaging affects the quantity of fuel you use during its transport, especially by flight (Italy to USA, for example).”

La Bella, which is also based in Italy, has designed new packaging systems that reduce the weight and size of shipments, reducing its carbon footprint.

“For example, instead of paper envelopes inside string packaging to indicate which string is inside, we use paper straws printed with numbers (when a colored ball end is not an option),” a La Bella spokesperson said. “This way we’ve eliminated the use of envelopes unlike most competitors. Further, when packaging groups of sets that get shipped to stores or distributors, we use a banding system instead of cardboard boxes.”

Hannabach CEO Viktor Fonfara says the German company is considering a more environmentally friendly version of its poly zipper bag that protects strings from becoming tarnished. It also recycles some strings during the manufacturing process.

“What we do from our side in the production is that all the scrap materials are collected to be recycled – copper, silver, gold mainly,” he says.

Other attempts at recycling have taken a more creative approach.

The not-for-profit UK company Guitarwrist creates bespoke jewellery from artists’ used guitar strings. The profits go to the artist’s charity of choice.

No products found.