Coated guitar strings are a simple solution to help stop a guitar’s sound becoming dull as sweat, moisture, dirt and even humidity corrode the bass strings’ metal alloy. But while the evidence clearly shows they extend the life of strings, does the coating adversely affect their tone and feel?

Much research has been done on treble strings made of consistent material such as nylon or fluorocarbon. Thicker strings tend to be louder but less bright, while thinner strings are quieter but brighter-sounding, although this effect breaks down when it comes to wound bass strings, which create a heavier string without adding bending stiffness or damping.

“The simple link between overall diameter and damping is completely lost for wound strings: it all depends on the internal structure of the different layers used,” says Professor Jim Woodhouse.

However, many early patents still highlighted the acoustic issues caused by various coatings and treatments applied to strings – at least in the early days. Today’s guitarist can choose from a huge array of coated strings that matches their preference for feel, tone and longevity.

String coatings: some history lessons

Luthier David A. Santo was perhaps the first to launch coated guitar strings in the mid-1970s by applying a relatively thick 1.0 to 1.5 millimetre polytetrafluorethylene (PTFE) fluorocarbon resin (or Teflon) on the surface of his Santo Recording Guitar Strings. This coating filled in the small gaps between windings, where microscopic dirt and grime would accumulate.

Other manufacturers, soon followed with their own coated strings. However, there was no adhesive to securely hold some early coatings against the string. The result of these heavy or stiff wrappings was limited vibration of the string, deadening the string’s upper frequencies.

But coated strings continued to improve as more manufacturers began to experiment with new processes.

W. L. Gore & Associates – best known for its waterproof GORE-TEX fabric – launched its coated Elixir brand in May 1997. They cost about double a standard pack of strings which initially slowed growth, until they gave away thousands of boxes to musicians, including those attending the Berklee College of Music in Boston. It convinced many musicians that the price was worth it.

Elixir, D’Addario, and Ernie Ball now dominate the coated string market in North America, while other popular manufacturers include Martin, S.I.T, Black Diamond, DR Strings, Rotosound, LaBella, and Fender.

No products found.

Improving technology counters acoustic damping

Like-for-like tests that compare the same coated and uncoated strings are rare.

One of the first string coating patents by W.L. Gore from the late-1990s including extensive testing of coatings applied to commercially-manufactured strings. It found that a polytetrafluoroethylene (ePTFE) string covering causes the string to vibrate with more energy in the higher harmonics or overtones, although some specific frequencies were dampened.

“Human hearing, which peaks in sensitivity at around 3 kHz, is thus particularly sensitive to higher harmonics of these generally low pitched strings,” it said in the patent. “The subjective interpretation of greater intensity in higher harmonics is that the sound appears ‘brighter’ or ‘fuller’ for the inventive strings, even though one or more specific higher frequencies may be slightly attenuated when compared to the control string without a covering.”

The types of string coatings offered by W.L. Gore through its Elxir range has since expanded, effectively offering three broad choices of coating: POLYWEB coated strings (the original coating, which has a warmer tone with a slicker feel); NANOWEB (a slightly less thick coating, which has a brighter tone and smoother feel) or OPTIWEB (aimed at replicating the sound of an uncoated string).

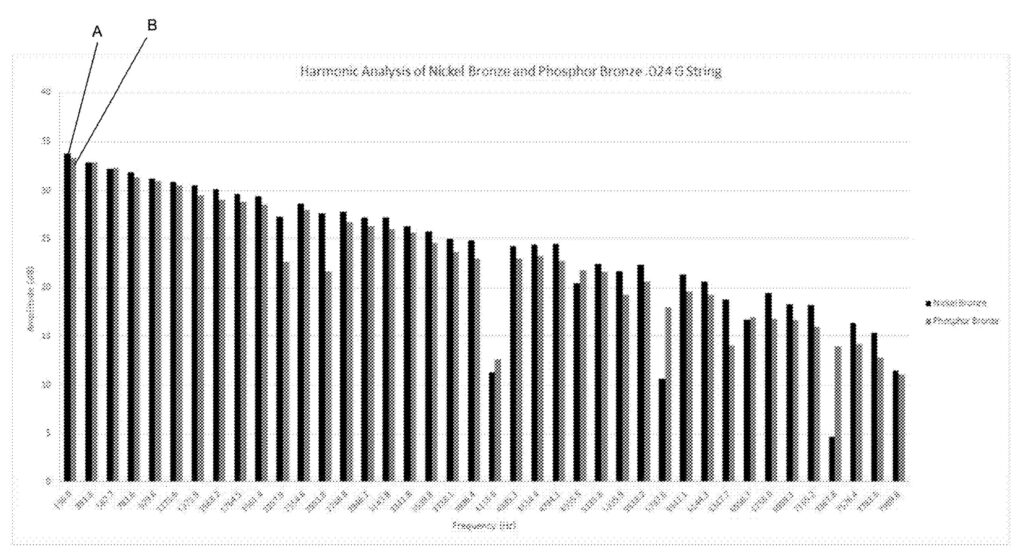

A more recent patent application by D’Addario included the graph below comparing harmonic data of a coated nickel-plated bronze string (String A: left bars) and an uncoated phosphor bronze string (String B: right bars). Both strings showed similar amplitude at all harmonic frequencies (although both strings were of 0.024 gauge size – the G string – which has the least wire wrapping.)

D’Addario still acknowledged that using a polymeric material to coat the winding wire on copper-based bronze alloy bass strings, or even applying a coating to finished bass strings, using popular coating processes could cause acoustic issues.

“Unfortunately, the introduction of any flexible, polymeric material such as those described above creates acoustical damping that diminishes the crispness in tone of the new string. The coating, whether on the winding wire or the finished wound strings, will reduce the output of the upper partial harmonics polymeric material.”

D’Addario said its new string coating process avoided such issues. The company first launched its EXP (Extended Play) strings for classical guitar in 2002 and refined the string coating process several times over the years. In 2019, it replaced the EXP line with the XT range – a totally new process that treats the wrap wire. In 2021 it launched the XS line of coated strings, which uses a different process that makes the strings last longer than the XT range.

No products found.

Benefits of coated strings

String choice is a deeply personal choice for guitarists. Many have become converts to the benefits of coated strings – particularly acoustic guitarists who rarely have the benefits of amplification to modify their sound – while others are yet to be convinced.

But as the technology has improved over the past three decades, the benefits have naturally come to the fore.

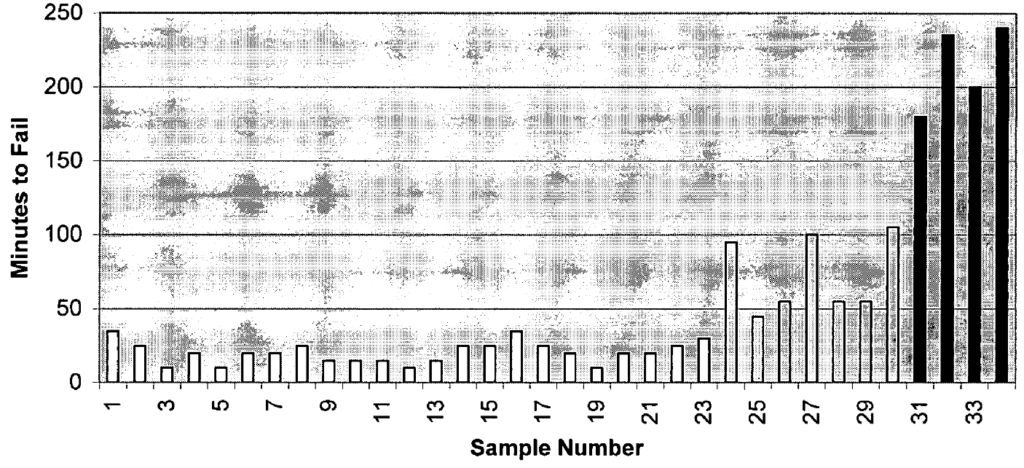

Strings last longer. Coated strings typically last three to five times as long as traditional uncoated strings, more than justifying their higher price point. Sweat and grime is less prone to build up in the gaps between the string winding, which is the main reason strings lose their harmonic lustre. This can be crucial, particularly for players who naturally sweat more or who live in humid climates. The diagram below, from a 2007 W.L. Gore patent application, shows the results of a rotating wheel of picks striking wound strings at a constant rate of 0.8 inch per second. The longest lasting samples 31-34 were treated with the Elixir coating.

Longer shelf life. Re-stringing a guitar only to find the strings are already dead should never happen. But it does occur given strings can sit for months or even years in their packing, where they can oxidise when exposed to air. This is less likely to occur with coated strings which have an extra layer of protection beyond packaging.

Less string friction. The polymer coating on strings makes them smoother, reducing squeaking when changing position. This can generally make it easier to play the instrument, although some guitarists find coatings make the strings slippery under their fingers. It depends on the type and thickness of the coating, as well as the player’s preference.

No products found.

A Short History of Coated Guitar Strings

1975: David A. Santo introduced the Santo Recording Guitar Strings, which had a thin (1.0 to 1.5 mil) deposit of poly tetrafluorethylene (PTFE) fluorocarbon resin (i.e., Teflon brand material) on the surface of both unitary and wound guitar strings.

1990s: Companies including W.L. Gore & Associates, D’Addario, and Rohrbacher Technologies apply for string coating patents.

May 1997: W. L. Gore & Associates launches its Elixir brand. Sales are initially slow given the strings higher price point but Elixir grows to dominate the acoustic string market.

Jan 2002: D’Addario launches its EXP Classical strings (Extended Play Coated Strings range).

Jan 2005: D’Addario launches redesigned EXP classical strings in silver-plated copper at a lower price.

2008: Ernie Ball launches its Titanium Reinforced Coated Slinky Acoustic Strings.

Jan 2010: D’Addario launches the EXP coated strings for electric guitar.

2014: LaBella launches its Vapor Shield electric, acoustic and bass string range.

Feb 2017: Elixir launches the OPTIWEB electric guitar strings line.

June 2019: D’Addario replaces the EXP line with the XT range of coated strings, which used a new string coating process.

April 2021: D’Addario launches the XS range of coated strings.

May 2022: – D’Addario expands the XS range to include coated strings for electric guitar.

No products found.